# The Enduring Pull: Exploring Ring of Magnets, Strength, and Magnetic Fields

**Summary:** This article dives deep into the fascinating world of ring magnets. From understanding their unique magnetic properties and the science behind their strength to exploring their diverse applications in everything from motors and sensors to art and everyday life, we’ll uncover why ring magnets maintain such a captivating allure. Discover practical tips for handling, safety, and even DIY projects using these powerful magnetic components.

## Understanding the Magnetic Field of Ring Magnets

Ring magnets, unlike bar magnets, possess a distinct magnetic field. This field is not simply a linear flow from one pole to the other. Instead, it’s a toroidal field – a donut-shaped field that circulates through the magnet’s body and extends outwards. This geometry significantly influences how a ring magnet interacts with other materials, including other magnets or ferromagnetic substances. The strength and shape of the field depend heavily on the magnet’s material, dimensions (diameter, thickness, and height), and its magnetization. Finite Element Analysis (FEA) software is often used to precisely model and predict these complex magnetic fields.

The specific orientation of the magnetization vector within the ring magnet is crucial. For example, a diametrically magnetized ring magnet will have a very different field compared to an axially magnetized one. The former creates a strong field concentrated near the poles (located on opposite sides of the ring’s outer circumference), while the latter produces a field similar, but more complex than that of a disc magnet, focused around the flat faces. Understanding these field characteristics is essential for effectively using ring magnets in various applications. Furthermore, the presence of imperfections or non-uniform magnetization can significantly distort the expected field pattern, leading to reduced performance. Careful manufacturing processes are therefore essential for producing high-quality ring magnets with predictable and consistent magnetic properties.

## Materials Matter: Neodymium vs. Ferrite Ring Magnets

The choice of material directly dictates a ring magnet’s strength, temperature stability, and cost. Two of the most common materials are neodymium (NdFeB) and ferrite (ceramic) magnets. Neodymium magnets boast exceptionally high strength for their size, making them ideal for applications where compactness is a key requirement. They are, however, more expensive than ferrite magnets and more susceptible to temperature-induced demagnetization if certain grades aren’t selected. Different grades of neodymium exist (e.g., N35, N42, N52), with higher numbers indicating a stronger magnetic field. Consider corrosion resistance as well; neodymium magnets often require a protective coating (nickel, epoxy, etc.) to prevent rusting.

Ferrite ring magnets, on the other hand, are a more cost-effective alternative. Though weaker than neodymium, they offer excellent resistance to corrosion and operate reliably at higher temperatures. These characteristics make them well-suited for applications in motors and generators where exposure to heat is inevitable. Ferrite magnets are also magnetically “hard,” meaning they are resistant to demagnetization by external fields. The trade-off is a lower energy product compared to neodymium, requiring larger magnet volumes to achieve the same magnetic force. Ultimately, selecting the right material involves carefully weighing the application’s performance requirements against budget constraints and environmental conditions.

## Measuring Magnetic Strength: Gauss, Tesla, and Pull Force

Understanding the units used to quantify magnetic strength is crucial for comparing different ring magnets and selecting the appropriate one for a specific task. Gauss and Tesla are units of magnetic flux density, representing the strength of the magnetic field at a particular point. Tesla is the SI (International System of Units) unit, with 1 Tesla equaling 10,000 Gauss. A higher Gauss or Tesla value indicates a stronger magnetic field at that point. Magnetic flux density is typically measured using a Gaussmeter or a Teslameter.

However, magnetic flux density doesn’t directly translate to the amount of force a magnet can exert. Pull force, also known as holding power, is a more practical measure in many applications. It represents the amount of force required to detach the magnet from a flat steel plate. Pull force is typically measured in pounds or kilograms. While a higher magnetic flux density generally implies a greater pull force, the relationship is not linear and is influenced by factors like the magnet’s shape, the surface area in contact with the steel plate, and the air gap between the magnet and the plate. Manufacturers typically provide pull force data for their magnets, measured under specific conditions.

## Applications Galore: From Motors to Medicine with Magnetic Rings

Ring magnets are ubiquitous, finding applications in a wide range of industries and everyday products. In electric motors, they are essential components in creating rotational motion. Arranged around a central rotor, they interact with electromagnets to generate the torque that drives the motor. Their precise size and magnetic characteristics are carefully engineered to optimize motor performance and efficiency. Linear actuators also rely on ring magnets for precise and controlled linear movements, finding use in automation systems and medical devices.

Beyond motors, ring magnets play crucial roles in sensors. Their consistent magnetic field can be used to detect position, speed, or proximity. For instance, a ring magnet attached to a rotating shaft can trigger a Hall-effect sensor, providing information about the shaft’s rotational speed. In medical applications, ring magnets are used in Magnetic Resonance Imaging (MRI) machines, creating the strong magnetic field necessary for generating detailed images of the human body. Their applications also extend to magnetic bearings, loudspeakers, magnetic separation and purification, and even holding and fastening applications around the house.

## Safety First: Handling and Storage of Ring Magnets

Ring magnets, particularly neodymium magnets, can be surprisingly powerful, posing potential hazards if not handled with care. Their strong attraction can cause them to snap together with significant force, potentially pinching fingers or damaging the magnets themselves. Always wear gloves when handling strong magnets, and keep them away from sensitive electronic devices like pacemakers, credit cards, and computer hard drives.

Proper storage is also essential to maintain the magnets’ integrity and prevent accidents. Store them in a safe place away from children and pets. Keep them separated from other magnets to prevent them from snapping together. If storing neodymium magnets, ensure the environment is dry to prevent corrosion. For long-term storage, consider wrapping each magnet individually in paper or plastic to protect the coating and prevent scratching. A non-magnetic container like a plastic box is ideal for organizing and storing multiple ring magnets.

## DIY Projects and Creative Uses with Magnetic Rings

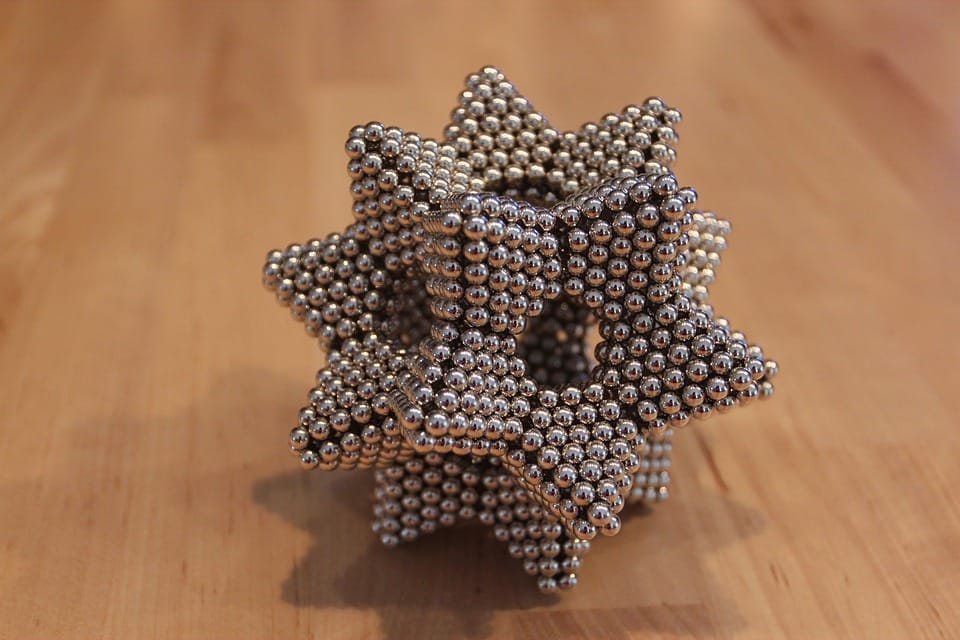

The accessibility of ring magnets has sparked numerous DIY projects and creative applications. From building simple magnetic stirrers for science experiments to creating innovative closures for jewelry boxes, their versatility is limited only by imagination. Small ring magnets can be embedded in cabinet doors to provide secure closures, eliminating the need for latches. Larger ring magnets can be used to create magnetic knife racks, keeping knives safely and conveniently within reach in the kitchen.

Artists and crafters also leverage ring magnets for their unique properties. They can be incorporated into sculptures, enabling interactive elements or creating the illusion of floating objects. Ring magnets can be attached to miniature figurines, allowing them to be displayed on metal surfaces or used as magnetic pieces for board games. When undertaking DIY projects involving ring magnets, prioritize safety measures and research proper handling techniques.

## Optimizing Performance: Air Gaps, Shielding, and Orientation

To maximize the effectiveness of a ring magnet in a specific application, it’s crucial to consider factors like air gaps, shielding, and magnet orientation. An air gap between the magnet and the object it’s attracting significantly reduces the magnetic force. Minimizing the air gap is essential for achieving optimal performance. This can be achieved through careful design and precision manufacturing. Adding a steel backing plate can help concentrate the magnetic flux and improve the pull force, especially when there is an air gap.

Magnetic shielding involves using materials with high permeability to redirect the magnetic field away from sensitive components or to confine it to a specific area. This is particularly important in applications where stray magnetic fields could interfere with electronic devices or other magnets. The correct orientation of the magnet, relative to other magnets or ferromagnetic materials, is also vital for achieving the desired interaction. Experimentation and careful analysis of the magnetic circuit are often required to determine the optimal configuration.

## The Future of Ring Magnets: Advancements and Innovations

The field of magnetics is constantly evolving, with ongoing research and development leading to new advancements and innovations in ring magnet technology. Researchers are exploring new materials with even higher energy products, enabling the production of smaller and more powerful magnets. Additive manufacturing (3D printing) techniques are being developed to create magnets with complex shapes and customized magnetic properties.

Nanomaterials and nanocomposites are also being investigated as potential building blocks for future magnets, offering the promise of enhanced performance and novel functionalities. These advancements are expected to expand the applications of ring magnets even further, driving innovation in fields like electric vehicles, renewable energy, and medical technology. The demand for permanent magnets is rising globally, and ring magnets, with their versatility and specific attributes, are poised to play a significant role in shaping these future technologies.

## Conclusion

Ring magnets, with their characteristic toroidal field and diverse material compositions, stand as indispensable components across numerous industries. From ensuring the smooth operation of electric motors to enabling cutting-edge medical imaging and facilitating creative DIY endeavors, their influence is undeniable. This article has explored the fundamental properties, safety considerations, and optimization techniques associated with ring magnets. By understanding their intricacies, we can harness their power effectively and unlock their full potential. As materials science and manufacturing techniques continue to advance, the future of ring magnets promises even greater capabilities and broader applications, shaping the technologies of tomorrow.

## FAQ

### H3 What are the key differences between neodymium and ferrite ring magnets?

Neodymium ring magnets are significantly stronger for their size than ferrite ring magnets, making them suitable for applications where space is limited. However, they are more expensive and can be more susceptible to temperature-induced demagnetization and corrosion. Ferrite ring magnets are more cost-effective, possess excellent corrosion resistance, and perform reliably at higher temperatures, though they are magnetically weaker.

### H3 How do I measure the strength of a ring magnet?

The strength of a ring magnet can be measured using several parameters. Magnetic flux density (measured in Gauss or Tesla) indicates the strength of the magnetic field at a particular point. Pull force (measured in pounds or kilograms) represents the amount of force required to detach the magnet from a flat steel plate. Gaussmeters and Teslameters measure magnetic flux density, while pull force is typically measured using a force gauge. Manufacturers usually provide pull force data for their magnets.

### H3 What safety precautions should I take when handling strong ring magnets?

Strong ring magnets can snap together with considerable force, potentially pinching fingers or damaging the magnets. Wear gloves when handling them. Keep them away from sensitive electronic devices like pacemakers, credit cards, and computer hard drives. Store them in a safe place away from children and pets, and keep them separated from other magnets to prevent accidents. Avoid subjecting neodymium magnets to high temperatures or humid environments to prevent demagnetization and corrosion.

### H3 Can I use ring magnets in DIY projects?

Yes, ring magnets are excellent for DIY projects. They can be used to create magnetic closures, knife racks, magnetic stirrers, and various other creative applications. Always prioritize safety when working with magnets and research proper handling techniques before starting a project. Ensure you select the appropriate magnet size and strength for the intended use and take precautions to protect yourself and others from potential hazards.

### H3 How does an air gap affect the performance of a ring magnet?

An air gap, the space between the magnet and the object it is attracting, significantly reduces the magnetic force. Minimizing the air gap is crucial for achieving optimal performance. Adding a steel backing plate can help concentrate the magnetic flux and improve the pull force, especially when an air gap is unavoidable.

### H3 What is magnetic shielding and when is it necessary?

Magnetic shielding involves using materials with high permeability to redirect the magnetic field away from sensitive components or to confine it to a specific area. It is necessary in applications where stray magnetic fields could interfere with electronic devices, other magnets, or sensitive instruments. Shielding materials, such as mu-metal, help minimize the impact of unwanted magnetic fields.

### H3 How does the orientation of a ring magnet affect its performance?

The orientation of the ring magnet, relative to other magnets or ferromagnetic materials, is vital for achieving the desired magnetic interaction. The specific orientation of the magnetization (axial vs. diametrical) determines the shape and distribution of the magnetic field, affecting the overall performance. Experimentation or magnetic circuit analysis might be necessary to determine the optimal configuration for a particular application.

### H3 What are some emerging trends in ring magnet technology?

Emerging trends in ring magnet technology include the development of new materials with higher energy products, enabling more compact and powerful magnets. Additive manufacturing (3D printing) techniques are being explored to create magnets with complex shapes and customized magnetic properties. Nanomaterials and nanocomposites are also being investigated as potential building blocks for future magnets.

### H3 Where can I purchase quality ring magnets for my applications?

Quality ring magnets are available from a variety of suppliers, both online and through specialized distributors. When selecting a supplier, consider factors such as the range of materials and sizes offered, the accuracy of the magnetic specifications, and the availability of technical support. Reading reviews and comparing prices from different suppliers is recommended to ensure you’re getting the best value. Before making a purchase, define your quality requirements to ensure the magnets meet the needs of your application.