# From Speakers to Motors: Exploring the Widespread Applications of Ferrite Magnets

Ferrite magnets are essential components in a vast range of devices, from the everyday speakers that amplify our music to the powerful motors that drive our machines. This article delves into the composition, properties, and diverse uses of ferrite magnets, highlighting their crucial role in modern technology and explaining why they remain a cost-effective and versatile magnetic solution. Discover why these unsung heroes are so pervasive in our lives.

## What are Ferrite Magnets? Understanding Their Composition and Properties

Ferrite magnets, also known as ceramic magnets, are a type of permanent magnet composed primarily of iron oxide (Fe2O3) and one or more other metallic elements, such as strontium (Sr), barium (Ba), or manganese (Mn). These materials are processed using powder metallurgy techniques, which involve mixing the powdered raw materials, pressing them into the desired shape, and then sintering them at high temperatures. Sintering fuses the particles together, creating a solid, hard, and permanent magnetic material.

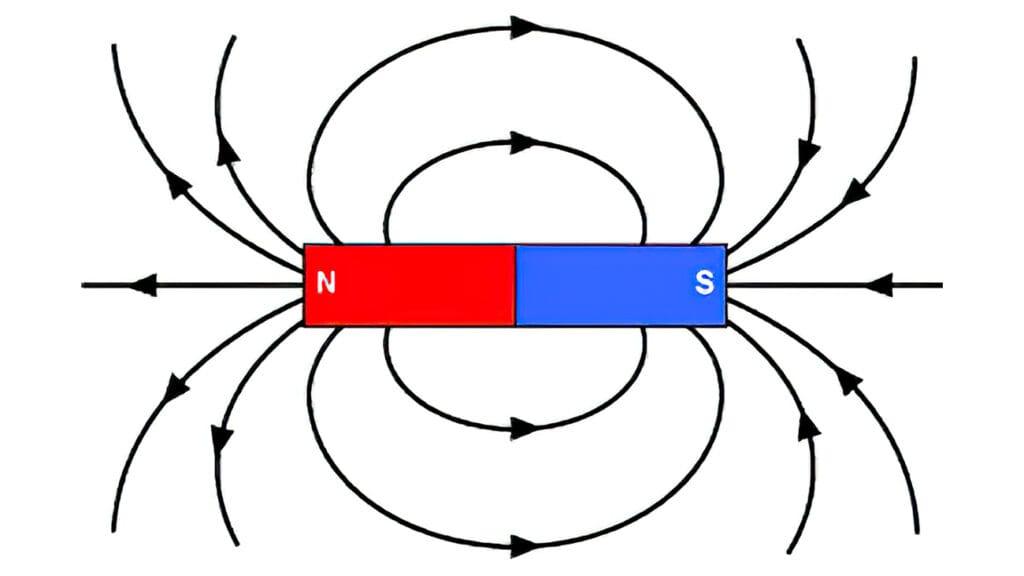

The unique properties of ferrite magnets stem from their crystalline structure and the alignment of magnetic domains within the material. They exhibit high coercivity, meaning they are resistant to demagnetization by external magnetic fields, making them suitable for applications where a stable magnetic field is required. Furthermore, ferrite magnets are electrically non-conductive, reducing eddy current losses and making them suitable for high-frequency applications. Their relatively low cost compared to other permanent magnets, such as neodymium or samarium cobalt, contributes to their widespread adoption.

## The Indispensable Role of Ferrite Magnets in Loudspeakers

One of the most recognizable applications of ferrite magnets is in loudspeakers. A loudspeaker employs a magnetic field to interact with an electric current flowing through a voice coil, ultimately converting electrical signals into audible sound waves. The ferrite magnet provides the static magnetic field necessary for this interaction.

In a typical loudspeaker, a ferrite ring magnet is strategically positioned around the voice coil, which is attached to the speaker cone. When an alternating current, representing the audio signal, flows through the voice coil, it generates a varying magnetic field. This field interacts with the strong, static magnetic field provided by the ferrite magnet. The interaction between the two magnetic fields causes the voice coil to move back and forth, which in turn moves the speaker cone, producing sound waves that we hear. The strength and quality of the ferrite magnet significantly impact the efficiency and performance of the loudspeaker.

## Ferrite Magnets Driving Performance in Electric Motors

Beyond loudspeakers, ferrite magnets play a critical role in electric motors, powering everything from household appliances to industrial machinery. In an electric motor, ferrite magnets create a static magnetic field that interacts with the rotating magnetic field generated by the motor’s windings. This interaction produces the torque that drives the motor’s shaft.

Ferrite magnets are commonly used in DC motors, stepper motors, and some types of AC motors. Their high coercivity ensures a stable magnetic field, enabling efficient and reliable motor operation. While more powerful rare earth magnets are often favored in high-performance applications, ferrite magnets offer a cost-effective solution for many motor applications where high power density is not critical. Furthermore, their resistance to demagnetization at higher temperatures makes them suitable for motors operating in demanding environments.

## Beyond Audio and Motion: Ferrite Magnets in Electronics

The applications of ferrite magnets extend far beyond audio and motor technologies. They are integral components in numerous electronic devices, performing a variety of critical functions.

Ferrite cores are widely used in inductors and transformers. The ferrite material concentrates the magnetic field, increasing inductance and improving the efficiency of energy transfer. This is particularly important in power supplies, where ferrite cores help to minimize losses and reduce electromagnetic interference (EMI). Ferrite beads, small cylindrical components, are also commonly used as filters to suppress unwanted high-frequency noise in electronic circuits. These beads absorb high-frequency energy, preventing it from propagating along the circuit board and interfering with other components.

## Cost-Effectiveness: Why Ferrite Magnets Remain a Popular Choice

Despite the availability of more powerful rare earth magnets, ferrite magnets remain a popular choice due to their cost-effectiveness. The raw materials used to manufacture ferrite magnets are abundant and relatively inexpensive compared to the rare earth elements required for neodymium or samarium cobalt magnets.

The manufacturing process for ferrite magnets is also well-established and efficient, further contributing to their lower cost. This makes them an attractive option for applications where high performance is not the primary concern and cost is a significant factor. For example, in many automotive applications, such as sensors and auxiliary motors, ferrite magnets provide a suitable balance of performance and cost. Their affordability allows manufacturers to incorporate magnetic components into a wider range of products, making advanced technologies more accessible.

## Advantages and Disadvantages: Weighing the Pros and Cons of Ferrite Magnets

While ferrite magnets offer numerous benefits, it’s crucial to consider their limitations alongside their advantages to determine the optimal magnet choice for a specific application.

One of the primary advantages of ferrite magnets is their high coercivity, which ensures resistance to demagnetization. They are also resistant to corrosion and offer good temperature stability. Furthermore, they are electrically insulating, minimizing eddy current losses in high-frequency applications. However, ferrite magnets have a significantly lower energy product compared to rare earth magnets, meaning they produce a weaker magnetic field for a given volume. They are also brittle and prone to cracking, requiring careful handling during manufacturing and assembly. Therefore, applications requiring very high magnetic fields or miniaturization may necessitate the use of more powerful, albeit more expensive, alternatives.

## Types of Ferrite Magnets: Exploring Strontium and Barium Ferrites

Within the category of ferrite magnets, two primary types stand out: strontium ferrite (SrFe12O19) and barium ferrite (BaFe12O19). Both materials belong to the magnetoplumbite family of oxides and share similar properties, but there are subtle differences that influence their suitability for specific applications.

Strontium ferrite is generally preferred due to its slightly higher magnetic performance and superior chemical stability. Its higher coercivity makes it more resistant to demagnetization, and its resistance to moisture and other environmental factors contributes to longer service life. Barium ferrite, while similar in properties, may be used in applications where cost is the overriding factor. Both materials are widely used in electric motors, loudspeakers, and magnetic separators. The specific choice between strontium and barium ferrite often depends on the precise performance requirements and cost constraints of the application.

## The Future of Ferrite Magnets: Innovations and Emerging Applications

Despite being a mature technology, the field of ferrite magnets continues to evolve with ongoing research and development aimed at improving their properties and expanding their applications.

Researchers are exploring new processing techniques to enhance the magnetic performance of ferrite magnets, such as grain refinement and advanced sintering methods. These efforts aim to increase the energy product and coercivity of ferrite magnets, making them more competitive with rare earth magnets in certain applications. Emerging applications for ferrite magnets include their use in high-frequency wireless communication devices, magnetic resonance imaging (MRI) systems, and energy harvesting technologies. As demand for cost-effective and environmentally sustainable magnetic solutions grows, ferrite magnets are poised to play an increasingly important role in a wide range of industries. The ongoing innovations ensure that ferrite magnets will remain a relevant and versatile magnetic material for years to come.

## Conclusion

Ferrite magnets, from their utilization in everyday speakers to their essential functions within electric motors, demonstrate remarkable versatility and cost-effectiveness. While not as powerful as their rare-earth counterparts, their high coercivity, resistance to demagnetization, and low cost make them indispensable components in a multitude of applications. From electronics to automotive components, ferrite magnets continue to play a vital role in modern technology, and ongoing innovations promise even broader applications in the future. Their enduring presence proves the value of a well-established, readily available, and reliable magnetic solution.

## FAQ

### What makes ferrite magnets different from other types of magnets?

Ferrite magnets differ from other types of magnets, such as neodymium or alnico magnets, primarily in their composition, magnetic properties, and cost. Ferrite magnets are composed of iron oxide and other metallic elements, making them relatively inexpensive. They have high coercivity, meaning they are resistant to demagnetization, and are electrically insulating. However, their energy product (a measure of magnetic strength) is lower compared to rare earth magnets.

### Are ferrite magnets environmentally friendly?

Compared to rare earth magnets, ferrite magnets are considered more environmentally friendly due to the abundance of their raw materials and the less energy-intensive manufacturing process. The mining and processing of rare earth elements can have significant environmental impacts. However, the disposal of ferrite magnets should still be handled responsibly to minimize potential environmental contamination.

### In what temperature range can ferrite magnets operate effectively?

Ferrite magnets generally have good temperature stability and can operate effectively in a temperature range from -40°C to +250°C (-40°F to +482°F). However, the specific temperature range can vary depending on the grade and composition of the ferrite magnet. Above their Curie temperature (around 450°C), they will lose their magnetism.

### Can ferrite magnets be used in high-speed applications?

Yes, ferrite magnets can be used in high-speed applications, particularly in electric motors. Their electrical insulating properties minimize eddy current losses, which are a concern in high-speed rotating machinery. However, the mechanical strength of ferrite magnets should be considered, as they are brittle and prone to cracking under high stress.

### How do I choose the right ferrite magnet for my application?

Choosing the right ferrite magnet for a specific application involves considering several factors, including the required magnetic field strength, the operating temperature range, the physical size and shape constraints, the cost limitations, and the mechanical stresses the magnet will experience. Consulting with a magnet supplier or engineer is recommended to ensure that the selected ferrite magnet meets the specific requirements of the application.