# Rare Earth Magnets: The Unseen Powerhouses Revolutionizing Modern Technology

**Summary:** This article delves into the fascinating world of rare earth magnets, exploring their unique properties, the specific rare earth elements involved, and the diverse applications that are transforming industries globally. From powering electric vehicles and wind turbines to enabling smartphones and advancements in medical imaging, we’ll uncover the secrets behind these powerful materials and their pivotal role in shaping the future of technology. Discover how the exceptional strength of these magnets is driving innovation and tackling some of the world’s most pressing challenges.

## The Extraordinary Strength of Rare Earth Magnets: A Deep Dive

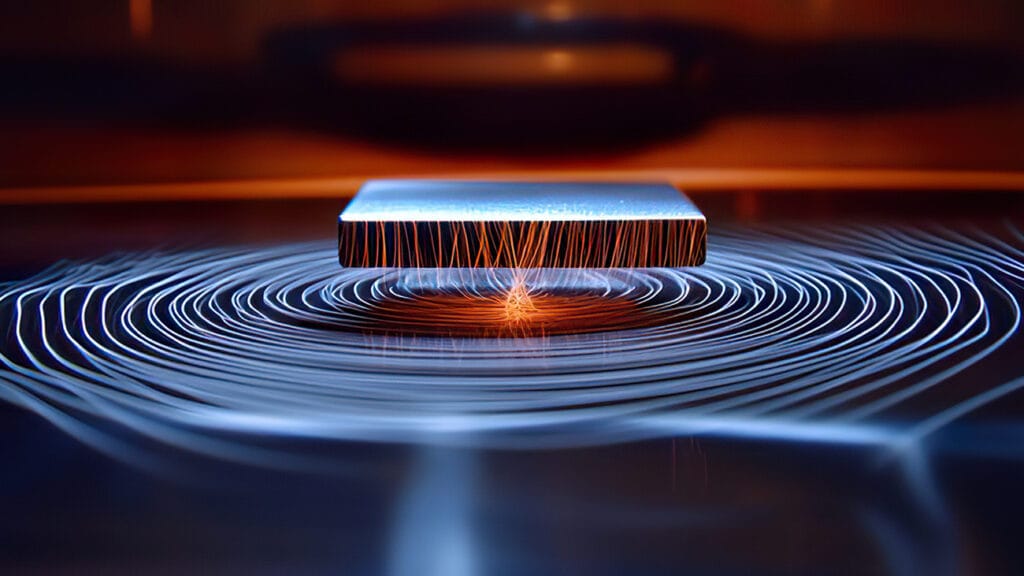

Rare earth magnets, unlike traditional magnets like ferrite or alnico, derive their exceptional strength from the unique electronic structure of the rare earth elements involved. These elements, primarily neodymium (Nd) and samarium (Sm), possess unpaired electrons in their inner electron shells, providing large magnetic moments. When combined with other elements like iron (Fe) and boron (B) in neodymium magnets (NdFeB), or cobalt (Co) in samarium-cobalt magnets (SmCo), these magnetic moments align to create a material with extraordinarily high energy density.

This high energy density translates into a much smaller magnet being able to produce a significantly stronger magnetic field. This is crucial in applications where miniaturization is key, such as in smartphones, headphones, and electric vehicle motors. The ability to generate such a strong magnetic field with such a compact size is what distinguishes rare earth magnets from their conventional counterparts and allows for a wider range of technological innovations. The strength is quantified by properties like coercivity (resistance to demagnetization) and energy product (a measure of magnetic field strength), which are significantly higher in rare earth magnets.

## Neodymium Magnets (NdFeB): The Workhorses of Modern Industry

Neodymium magnets, composed of neodymium, iron, and boron (NdFeB), are the most widely used type of rare earth magnet due to their exceptional magnetic strength and relatively lower cost compared to samarium-cobalt magnets. Their applications span nearly every industry, from consumer electronics to renewable energy to automotive. You’ll find them in the voice coil actuators of hard disk drives, in the speakers of your headphones and smartphones, and crucial components of large-scale wind turbines.

However, NdFeB magnets have some limitations. One significant drawback is their relatively low Curie temperature, meaning they lose their magnetism at relatively lower temperatures compared to SmCo magnets. They are also prone to corrosion, requiring protective coatings like nickel, zinc, or epoxy. Despite these drawbacks, continuous advancements in material science have led to improved coatings and modified compositions that enhance their temperature stability and corrosion resistance, ensuring their continued dominance in many applications. Different grades of NdFeB magnets exist, catering to different application requirements based on their specific magnetic properties.

## Samarium-Cobalt Magnets (SmCo): High-Temperature Performance

Samarium-cobalt (SmCo) magnets, consisting of samarium and cobalt, offer superior temperature stability and corrosion resistance compared to NdFeB magnets. While they are generally more expensive and have a slightly lower maximum energy product, their ability to maintain their magnetic properties at higher temperatures makes them ideal for applications in harsh environments, such as aerospace and military equipment.

You’ll find SmCo magnets in high-performance motors and generators, sensors operating in high-temperature environments, and specialized applications where corrosion resistance is paramount. They are also commonly used in high-end magnetic couplings and braking systems. The trade-off between cost and performance often dictates the choice between NdFeB and SmCo magnets, with SmCo preferred in situations where the operational environment is too demanding for NdFeB. The intrinsic coercivity and Curie temperature of SmCo magnets are significantly better than those of NdFeB magnets, making them the magnet of choice in demanding conditions.

## Rare Earth Magnets in Electric Vehicles: Powering the Future of Transportation

Electric vehicles (EVs) rely heavily on rare earth magnets, primarily NdFeB, for their electric motors. These magnets are crucial for achieving the high power density and efficiency required for EV propulsion. Hybrid electric vehicles (HEVs) also utilize rare earth magnets, although to a lesser extent than full EVs. The magnets are used in both the traction motor, which propels the vehicle, and in various auxiliary motors for systems like power steering, air conditioning, and braking.

The shift towards electric vehicles is driving significant demand for rare earth magnets, particularly neodymium. The efficient energy conversion and powerful torque provided by these magnets are essential for achieving satisfactory range and performance in EVs. However, the growing demand also raises concerns about the sustainability of rare earth mining and processing, prompting research into alternative magnet technologies and more sustainable mining practices. Reducing the reliance on rare earth elements in EV motors is an active area of research, with alternative motor designs and materials being explored.

## Wind Turbine Generators: Harnessing Renewable Energy

Large-scale wind turbines, particularly direct-drive turbines, utilize rare earth magnets in their generators to convert wind energy into electricity efficiently. Direct-drive turbines, which do not require a gearbox, rely on powerful generators with numerous magnets to generate electricity at low rotational speeds. NdFeB magnets are the most common choice due to their high energy density, although research is ongoing to reduce the dependence on rare earth elements in wind turbine generators.

The use of rare earth magnets in wind turbines contributes to their higher efficiency and reduced maintenance costs. The strong magnetic field generated by these magnets allows for a more compact generator design, which is beneficial in the often-restrictive space within the turbine nacelle. The growth of wind power as a renewable energy source further drives the demand for rare earth magnets, emphasizing the importance of responsible sourcing and recycling. Alternative generator designs using materials like ferrite magnets are being explored, but face challenges in achieving the same level of performance as those using rare earth magnets.

## Medical Applications: Advancing Diagnostics and Treatment

Rare earth magnets play critical roles in various medical applications, including magnetic resonance imaging (MRI) machines, targeted drug delivery, and magnetic hyperthermia cancer treatment. MRI scanners utilize powerful superconducting magnets, often cooled with liquid helium, to generate strong magnetic fields that allow for detailed imaging of the human body. In targeted drug delivery, magnetic nanoparticles containing rare earth elements can be guided to specific locations in the body using external magnets.

Magnetic hyperthermia uses magnetic nanoparticles to generate heat within tumors when exposed to an alternating magnetic field, destroying cancer cells while minimizing damage to healthy tissue. The high magnetic susceptibility of rare earth compounds makes them ideal for this application. These applications showcase the versatility and importance of rare earth magnets in advancing medical diagnostics and treatments, contributing to improved patient outcomes. The ongoing research aims to improve the efficiency and safety of these treatments.

## Consumer Electronics: Miniaturization and Enhanced Performance

From smartphones and headphones to hard disk drives and electric motors in various portable devices, rare earth magnets are essential components in a wide range of consumer electronics. Their high strength-to-size ratio allows for the miniaturization of devices without compromising performance. In smartphones, for example, tiny but powerful NdFeB magnets are used in the speakers, microphones, and haptic feedback systems.

Headphones utilize them in the voice coil actuators to generate sound, and hard disk drives rely on them for precise positioning of the read/write heads. The demand for smaller, more powerful, and energy-efficient electronic devices continues to drive the demand for rare earth magnets in these applications. As technology advances, the role of these magnets in enabling innovation in consumer electronics will continue to grow. Continuous improvements in magnet manufacturing processes are further enhancing their integration into smaller and more complex electronic devices.

## Challenges and Sustainability: Addressing Environmental Concerns

The mining and processing of rare earth elements pose significant environmental challenges, including habitat destruction, water pollution, and air pollution. The extraction process often involves the use of harsh chemicals, and the disposal of waste products can contaminate surrounding ecosystems. Additionally, the geopolitical concentration of rare earth production in a few countries raises concerns about supply chain security and potential monopolistic practices.

Addressing these challenges requires a multi-faceted approach, including the development of more sustainable mining and processing techniques, the promotion of recycling and reuse of rare earth magnets, and the diversification of supply chains. Research into alternative materials and magnet designs that reduce or eliminate the need for rare earth elements is also crucial. Stronger environmental regulations and international cooperation are essential to ensure the responsible and sustainable management of these critical resources. Investing in research and development of closed-loop recycling processes for rare earth magnets is crucial for minimizing environmental impact.

## The Future of Rare Earth Magnets: Innovation and Alternatives

The future of rare earth magnets will likely be shaped by a combination of innovation in magnet technology, the development of alternative materials, and a greater emphasis on sustainability. Researchers are exploring new magnet compositions that offer improved performance and reduced reliance on scarce or environmentally problematic rare earth elements. One promising area is the development of high-performance ferrite magnets that could potentially replace NdFeB magnets in certain applications.

Another area of focus is the optimization of magnet manufacturing processes to reduce material waste and energy consumption. Furthermore, advancements in recycling technologies are paving the way for more closed-loop systems that recover valuable rare earth elements from end-of-life products. The development of alternative materials and processes will be crucial for mitigating the environmental impacts of rare earth mining and ensuring a sustainable supply of magnets for future technological advancements. Research into materials such as iron-nitride and high-entropy alloys is demonstrating potential as replacements for rare earth magnets in some applications.

## Conclusion

Rare earth magnets are indispensable components in a vast array of modern technologies, powering everything from electric vehicles and wind turbines to smartphones and medical imaging equipment. Their exceptional magnetic strength, derived from the unique properties of rare earth elements like neodymium and samarium, enables miniaturization, enhances performance, and drives innovation across diverse industries. While their benefits are undeniable, the environmental and geopolitical challenges associated with their extraction and processing must be addressed through sustainable practices, alternative materials, and recycling initiatives. The future of rare earth magnets hinges on responsible resource management, technological advancements, and a concerted effort to mitigate their environmental footprint, ensuring a sustainable supply of these crucial materials for a rapidly evolving world.

## FAQ

### What are rare earth elements?

Rare earth elements (REEs), also known as rare earth metals, are a set of 17 metallic elements that share similar chemical properties. They include scandium (Sc), yttrium (Y), and the lanthanides (lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu)). Despite their name, many REEs are relatively abundant in the Earth’s crust, but they are rarely found in concentrated and economically viable deposits.

### What makes rare earth magnets so strong?

The extraordinary strength of rare earth magnets stems from the unique electronic structure of the rare earth elements they contain. These elements possess unpaired electrons in their inner electron shells, resulting in large magnetic moments. When combined with other elements, such as iron and boron in neodymium magnets or cobalt in samarium-cobalt magnets, these magnetic moments align to create a material with exceptionally high energy density. This high energy density allows for smaller magnets to generate much stronger magnetic fields compared to traditional magnets.

### What are the main types of rare earth magnets?

The two main types of rare earth magnets are neodymium magnets (NdFeB) and samarium-cobalt magnets (SmCo). Neodymium magnets are the most widely used due to their exceptional magnetic strength and relatively lower cost, but they have lower temperature stability and corrosion resistance compared to samarium-cobalt magnets. Samarium-cobalt magnets offer superior temperature stability and corrosion resistance, making them ideal for high-temperature applications, but they are generally more expensive.

### What are the environmental concerns associated with rare earth mining?

The mining and processing of rare earth elements can have significant environmental impacts, including habitat destruction, water pollution, and air pollution. The extraction process often involves the use of harsh chemicals, and the disposal of waste products can contaminate surrounding ecosystems. Additionally, the mining of rare earth elements can generate radioactive waste, which requires careful management and disposal.

### Are there alternatives to rare earth magnets?

Yes, there are ongoing research efforts to develop alternative materials and magnet designs that reduce or eliminate the need for rare earth elements. Some promising alternatives include high-performance ferrite magnets, iron-nitride magnets, and high-entropy alloy magnets. These alternatives may not yet match the performance of rare earth magnets in all applications, but they offer the potential to reduce reliance on scarce or environmentally problematic resources.

### Can rare earth magnets be recycled?

Yes, rare earth magnets can be recycled, and recycling is becoming increasingly important to reduce the environmental impact of rare earth mining and to ensure a sustainable supply of these critical materials. Recycling technologies are being developed to recover valuable rare earth elements from end-of-life products, such as electric vehicles, wind turbines, and electronic devices. However, recycling processes can be complex and costly, and further advancements are needed to improve their efficiency and economic viability.

### What is the Curie temperature of a magnet?

The Curie temperature is the temperature at which a ferromagnetic or ferrimagnetic material loses its permanent magnetic properties and becomes paramagnetic. Above the Curie temperature, the thermal energy becomes sufficient to overcome the exchange interactions that align the magnetic moments, resulting in a loss of long-range magnetic order. Each magnetic material has its own specific Curie temperature. For example, NdFeB magnets typically have a lower Curie temperature than SmCo magnets. The operational temperature of a magnet should be well below its Curie temperature to ensure stable magnetic performance.

### How are rare earth magnets used in MRI machines?

In MRI (Magnetic Resonance Imaging) machines, extremely strong and uniform magnetic fields are required to align the nuclear spins of atoms within the body. Superconducting magnets, often using alloys of niobium and titanium and cooled to extremely low temperatures using liquid helium, are used to generate these fields. While the primary field generation relies on superconductivity, small rare earth magnets can play a role in shimming the field, correcting for inhomogeneities, and ensuring the field’s uniformity across the entire imaging volume. Achieving exceptionally uniform magnetic fields is extremely important for producing clear and accurate MRI images, and smaller rare earth elements can be incorporated to correct for any field distortions.