# [Acme Magnetics] Unveils Revolutionary NeoForce™ Magnet: Powering the Future of Industrial Applications

**Summary:** Acme Magnetics is proud to announce the release of NeoForce™, a groundbreaking new permanent magnet designed to revolutionize industrial applications. Boasting unparalleled strength, exceptional thermal stability, and enhanced durability, NeoForce™ offers significant performance upgrades over existing solutions, enabling increased efficiency, reduced energy consumption, and improved operational lifespan across a wide range of industries. Read on to discover how NeoForce™ is set to redefine magnetic capabilities in manufacturing, energy, transportation, and beyond.

## Understanding the Need for Next-Generation Industrial Magnets

Industrial magnets are the unsung heroes of countless processes, powering everything from electric motors and generators to separation equipment and medical devices. However, the increasing demands placed on these systems require magnets with improved performance characteristics. Existing magnet technologies often struggle with limitations in strength, thermal stability, and resistance to demagnetization, hindering efficiency and reliability. The development of NeoForce™ addresses these challenges directly, providing a robust and high-performing solution for the demanding environments of modern industry.

The current landscape of industrial magnets is dominated by materials like ferrite, alnico, and neodymium iron boron (NdFeB), each with its own set of advantages and disadvantages. Ferrite magnets, while cost-effective, offer relatively low strength. Alnico magnets exhibit excellent thermal stability but are prone to demagnetization. NdFeB magnets provide the highest strength but can suffer from performance degradation at elevated temperatures and are susceptible to corrosion. Acme Magnetics recognized the need for a magnet that combines the best qualities of existing technologies while mitigating their drawbacks, leading to the development of NeoForce™.

NeoForce™ represents a significant leap forward, combining advanced material science with innovative manufacturing techniques. The development process involved extensive research into new alloy compositions, sophisticated sintering processes, and advanced coating technologies. The result is a magnet that surpasses conventional materials in terms of magnetic strength, thermal resilience, and overall durability, enabling applications previously considered impractical or impossible. This new generation of magnets empowers engineers and manufacturers to design more efficient, powerful, and reliable industrial systems.

## Introducing NeoForce™: The Pinnacle of Magnetic Performance

NeoForce™ is a high-performance permanent magnet based on a novel combination of rare earth elements and proprietary doping agents. This unique composition provides exceptional magnetic strength, surpassing even the strongest NdFeB magnets in certain performance metrics. Furthermore, NeoForce™ exhibits significantly improved thermal stability, allowing it to maintain its magnetic properties at higher operating temperatures, a critical advantage in demanding industrial environments.

The key differentiator of NeoForce™ lies in its tailored microstructure and optimized grain alignment. Through advanced sintering techniques, Acme Magnetics has achieved a highly uniform and dense microstructure, minimizing defects and maximizing magnetic performance. This careful control over the material’s microstructure also enhances its resistance to demagnetization, ensuring long-term reliability and consistent performance over the lifespan of the application.

Beyond its superior magnetic properties, NeoForce™ incorporates a multi-layered protective coating that provides exceptional resistance to corrosion and oxidation. This coating, developed in-house by Acme Magnetics’ materials science team, significantly extends the lifespan of the magnet, even in harsh operating conditions where exposure to moisture, chemicals, or extreme temperatures is unavoidable. This robustness translates into reduced maintenance costs and extended operational uptime for industrial equipment utilizing NeoForce™.

## Superior Magnetic Strength and Energy Product

The magnetic strength of a magnet is a crucial factor in determining its performance in various applications. NeoForce™ boasts a significantly higher remanence (Br) and coercivity (Hc) compared to traditional magnets. Remanence refers to the strength of the magnetic field remaining in the magnet after the magnetizing field is removed, while coercivity indicates the magnet’s resistance to demagnetization. NeoForce™ delivers exceptional values in both these parameters, ensuring a strong and stable magnetic field.

The energy product (BHmax) is another key metric used to evaluate the overall performance of a permanent magnet. It represents the maximum energy that the magnet can store and deliver, and it directly correlates with its ability to perform useful work. NeoForce™ exhibits a significantly higher energy product than conventional magnets, indicating its superior ability to generate powerful magnetic fields for a given volume. This higher energy product translates into smaller, lighter, and more efficient designs for industrial equipment, such as motors, generators, and magnetic separators.

The superior magnetic strength and energy product of NeoForce™ allows for miniaturization of components without sacrificing performance. This is particularly beneficial in applications where space is limited, such as portable medical devices or compact electric motors. Furthermore, the increased strength can lead to improved efficiency and reduced energy consumption, contributing to lower operating costs and a smaller environmental footprint. In applications like wind turbine generators, stronger magnets allow for smaller and lighter generators, reducing material costs and structural loads.

## Unparalleled Thermal Stability for Reliable Operation

Thermal stability is a critical consideration for magnets used in high-temperature environments. Many magnet materials, particularly NdFeB, experience a significant drop in performance at elevated temperatures, limiting their applicability in certain industrial processes. NeoForce™ is engineered to overcome this limitation, maintaining its magnetic properties at temperatures significantly higher than conventional alternatives.

Acme Magnetics’ proprietary alloy composition and advanced sintering process contribute to the exceptional thermal stability of NeoForce™. By carefully controlling the microstructure and composition of the magnet, the Curie temperature (the temperature at which a ferromagnetic material loses its magnetism) has been significantly increased. This allows NeoForce™ to operate reliably at higher temperatures without experiencing significant demagnetization or performance degradation.

The enhanced thermal stability of NeoForce™ expands its applicability to a wider range of industrial applications, including high-speed electric motors, power generators operating at elevated temperatures, and downhole drilling equipment used in the oil and gas industry. The ability to maintain consistent performance at high temperatures ensures reliable operation and reduces the risk of failures caused by thermal demagnetization. This ultimately translates into increased uptime, reduced maintenance costs, and improved overall productivity.

## Enhanced Durability and Corrosion Resistance

Industrial environments often expose magnets to harsh conditions, including moisture, corrosive chemicals, and mechanical stress. Traditional magnets are susceptible to corrosion and degradation, which can lead to performance loss and premature failure. NeoForce™ is engineered to withstand these challenges, boasting enhanced durability and excellent resistance to corrosion.

The enhanced durability of NeoForce™ stems from two key factors: its optimized microstructure and its multi-layered protective coating. The dense and uniform microstructure minimizes internal stresses and reduces the susceptibility to cracking and chipping. The proprietary protective coating provides a barrier against moisture, corrosive chemicals, and oxidation, preventing degradation of the underlying magnetic material. This robust coating ensures long-term performance and reliability, even in the most demanding environments.

The superior corrosion resistance of NeoForce™ reduces the need for frequent replacements, minimizing downtime and maintenance costs. This is particularly important in applications where access to the magnet is difficult or hazardous, such as submersible pumps, offshore wind turbines, and underground mining equipment. The extended lifespan of NeoForce™ translates into significant cost savings over the lifetime of the equipment.

## Versatile Applications Across Diverse Industries

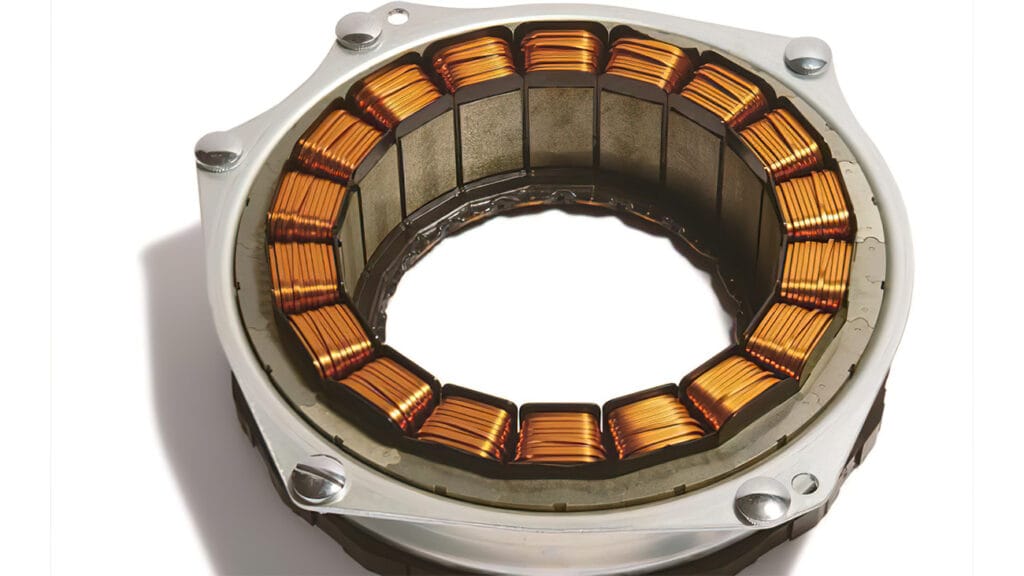

NeoForce™ offers a versatile solution for a wide range of industrial applications across diverse industries. Its superior magnetic strength, thermal stability, and durability make it ideal for applications where high performance and long-term reliability are critical requirements. From electric motors and generators to magnetic separation systems and medical devices, NeoForce™ is poised to revolutionize magnetic technology.

In the transportation industry, NeoForce™ can be used to develop more efficient and powerful electric motors for electric vehicles and hybrid vehicles. Its superior magnetic strength allows for smaller and lighter motors, improving fuel efficiency and reducing emissions. In the energy sector, NeoForce™ can enhance the performance of wind turbine generators, allowing for higher energy output and reduced operating costs. In manufacturing, NeoForce™ can be used in magnetic grippers, lifting devices, and separation systems to improve efficiency and productivity.

The versatility of NeoForce™ extends beyond these specific examples. Its exceptional properties make it a viable solution for a vast array of applications where high-performance magnets are required. Acme Magnetics is committed to working closely with customers to identify and develop new applications for NeoForce™, driving innovation and improving performance across various industries.

## Eco-Friendly Manufacturing and Sustainable Practices

Acme Magnetics is committed to sustainable manufacturing practices and minimizing the environmental impact of its products. The production of NeoForce™ incorporates eco-friendly processes and strives to reduce waste and energy consumption. The company is actively engaged in research and development to explore alternative materials and manufacturing techniques that further reduce the environmental footprint of its products.

The neodymium and other rare earth elements used in NeoForce™ are sourced from responsible mining operations that adhere to strict environmental and ethical standards. Acme Magnetics is committed to ensuring that its supply chain is transparent and sustainable. The company also actively participates in recycling programs to recover valuable materials from end-of-life magnets, reducing the demand for virgin resources.

By choosing NeoForce™, customers can contribute to a more sustainable future. The enhanced efficiency and extended lifespan of NeoForce™ equipped devices translates to reduced energy consumption and lower greenhouse gas emissions. Acme Magnetics is dedicated to providing high-performance magnetic solutions that are both environmentally responsible and economically viable.

## Availability and Customization Options

NeoForce™ is available in a variety of standard shapes and sizes, catering to a wide range of industrial applications. Acme Magnetics also offers custom design and manufacturing services to meet specific customer requirements. The company’s team of experienced engineers and material scientists work closely with customers to develop tailored solutions that optimize performance and minimize costs.

The availability of NeoForce™ is constantly expanding as Acme Magnetics invests in increased production capacity and enhanced distribution networks. Customers can purchase NeoForce™ directly from Acme Magnetics or through authorized distributors. The company provides comprehensive technical support and application engineering services to assist customers in selecting the optimal magnet solution for their specific needs.

Acme Magnetics is committed to providing exceptional customer service and ensuring that its customers have access to the resources and expertise they need to successfully integrate NeoForce™ into their products. The company offers a comprehensive range of support services, including application simulations, magnetic circuit design assistance, and on-site technical support.

## Conclusion

The launch of NeoForce™ marks a significant milestone in the field of industrial magnet technology. Its superior magnetic strength, unparalleled thermal stability, enhanced durability, and eco-friendly manufacturing practices make it a game-changing solution for a wide range of applications across diverse industries. Acme Magnetics is confident that NeoForce™ will empower engineers and manufacturers to develop more efficient, powerful, and reliable industrial systems, driving innovation and contributing to a more sustainable future. This next-generation magnet is poised to redefine magnetic capabilities and unlock new possibilities in manufacturing, energy, transportation, and beyond. NeoForce™ is not just a magnet; it’s a force for progress.

## FAQ

### What are the key advantages of NeoForce™ over traditional magnets?

NeoForce™ offers several key advantages over traditional magnets, including superior magnetic strength and energy product, unparalleled thermal stability, enhanced durability and corrosion resistance, and eco-friendly manufacturing practices. These advantages translate into improved performance, reduced maintenance costs, and increased energy efficiency.

### In what industries can NeoForce™ be used?

NeoForce™ is applicable across a wide range of industries, including transportation (electric vehicles, hybrid vehicles), energy (wind turbine generators, power generators), manufacturing (magnetic grippers, lifting devices, separation systems), medical devices, and many others. Its versatility makes it suitable for any application where high-performance permanent magnets are required.

### Is NeoForce™ more expensive than traditional magnets?

While NeoForce™ may have a higher initial cost compared to some traditional magnets, its superior performance and extended lifespan can result in significant cost savings over the lifetime of the equipment. The reduced maintenance costs, increased energy efficiency, and improved reliability contribute to a lower total cost of ownership.

### How does Acme Magnetics ensure the ethical sourcing of rare earth elements used in NeoForce™?

Acme Magnetics is committed to ethical sourcing and works with responsible mining operations that adhere to strict environmental and ethical standards. The company maintains a transparent supply chain and actively participates in recycling programs to reduce the demand for virgin resources.

### Can NeoForce™ magnets be customized to meet specific application requirements?

Yes, Acme Magnetics offers custom design and manufacturing services to tailor NeoForce™ magnets to meet specific customer requirements. The company’s team of experienced engineers and material scientists work closely with customers to develop optimized solutions.

### What kind of support does Acme Magnetics provide to customers using NeoForce™?

Acme Magnetics provides comprehensive technical support and application engineering services, including application simulations, magnetic circuit design assistance, and on-site technical support. The company is committed to ensuring that its customers have the resources they need to successfully integrate NeoForce™ into their products.

### What is the operating temperature range for NeoForce™ magnets?

NeoForce™ magnets exhibit exceptional thermal stability and can operate reliably at significantly higher temperatures than conventional NdFeB magnets. The specific operating temperature range depends on the grade and geometry of the magnet, but generally, it can withstand temperatures up to [Insert Temperature Value] without significant performance degradation. Please consult the product datasheet for specific details.

### How does the protective coating enhance the durability of NeoForce™ magnets?

The multi-layered protective coating on NeoForce™ magnets provides a robust barrier against moisture, corrosive chemicals, and oxidation. This prevents degradation of the underlying magnetic material, significantly extending the lifespan of the magnet, even in harsh operating conditions. The coating is specifically formulated to resist common industrial chemicals and environmental factors.